Medical

AEC chamber

The Ionisation Chambers are used as sensor elements for automatic X-ray exposure control units. They comprise air-filled parallel chambers with 1 or 3 measuring fields, coupled with an amplifier and a field selector. The low overall thickness of 6 mm ensures the chamber may be used with all modern X-ray equipment.

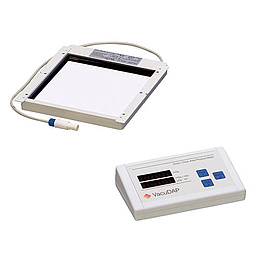

Principle of Operation

The current generated in the sensor fields by the X-rays will be amplified, digitized and fed to the automatic exposure controller. The AEC supplies the cut-off signal to the generator, and thereby ensures an optimal and reproducible image quality, independent of the radiation quality, object density, and other factors.

Chamber Electronics

The ionization chambers are supplied with a minimized chamber electronics, that amplify, digitize and process the generated current according to the field selection. The electronics also generate the chamber voltage without the need for an external high-voltage source.

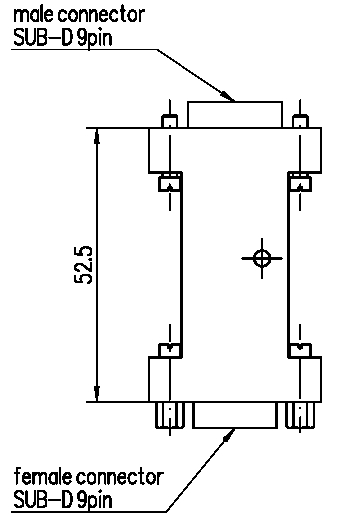

Ramp Module

In order to assure the backward compatibility with conventional interfaces a separate ramp module converts the pulses into a voltage ramp. This ramp module should be placed between interface cable and AEC interface on the generator site.